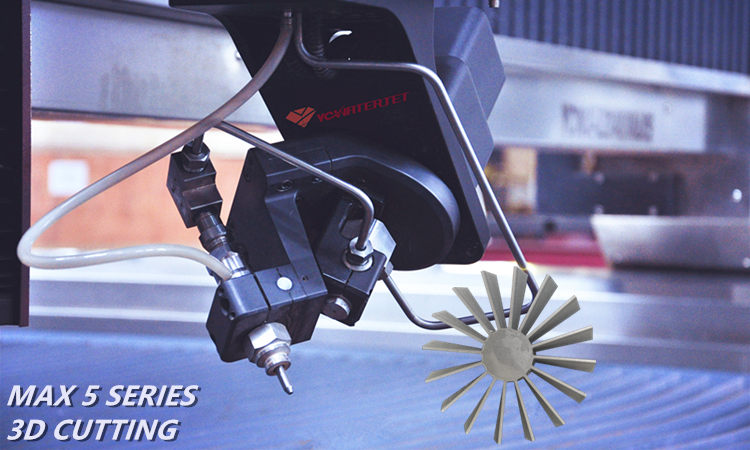

Máquina de corte por chorro de agua YC CNC de 5 ejes

Descripción del producto

Descripción del Producto:

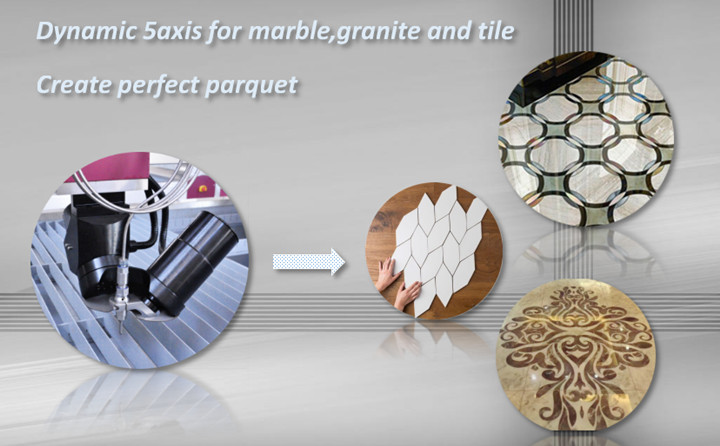

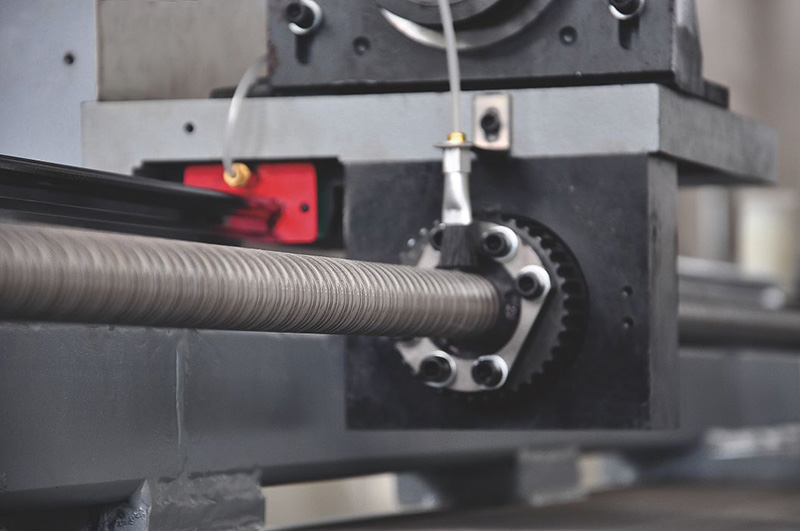

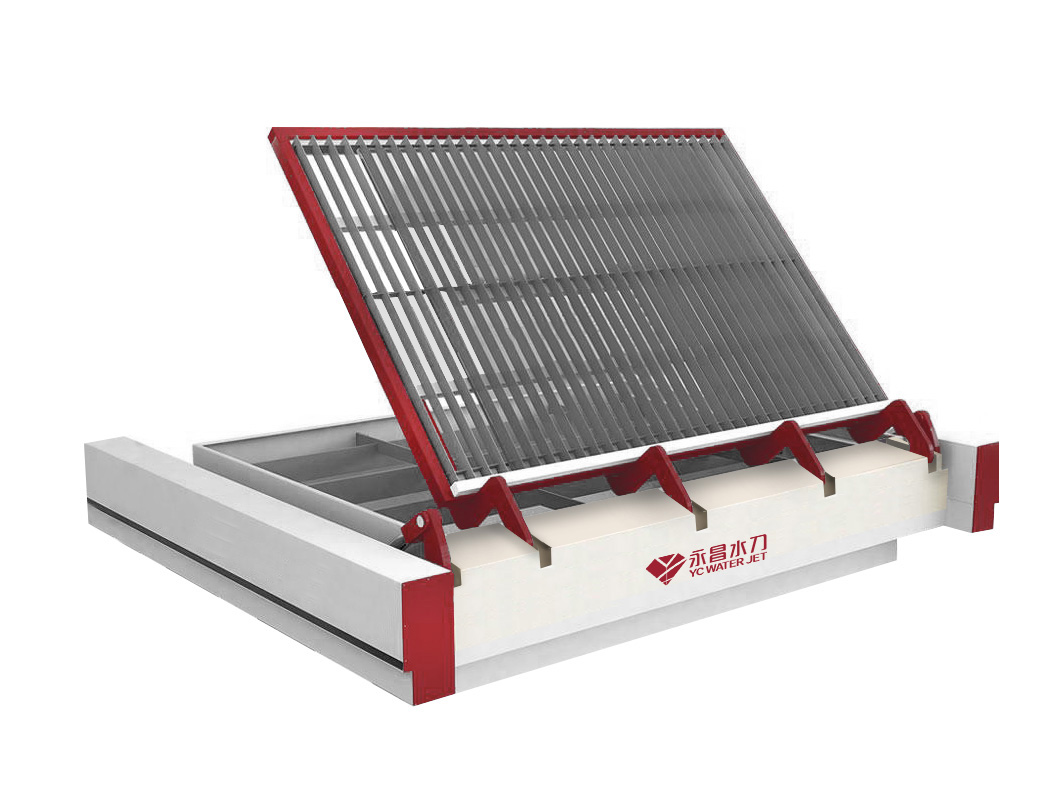

Debido a que el corte por chorro de agua es un tipo de corte flexible, la sección del producto cortada por la máquina de corte por chorro de agua CNC de tres ejes tradicional tendrá un cierto ángulo de inclinación, pero para garantizar la precisión de la sección de corte vertical, la velocidad de corte debe reducirse. La máquina de chorro de agua dinámica de 5 ejes YC puede garantizar la precisión de la sección de corte vertical compensando el ángulo de corte de ± 10 ° sin reducir la velocidad de corte.

Este tipo de máquina de corte por chorro de agua dinámica de 5 ejes es muy adecuada para cortar mármol y granito para hacer parquet de piedra, porque también se puede decir que es una máquina de corte en bisel. La piedra cortada no solo no necesita pulirse dos veces, sino que también ahorra tiempo y esfuerzo; pero también hace que los huecos del parquet sean más pequeños y el parquet del piso sea más perfecto.

Parametros del producto:

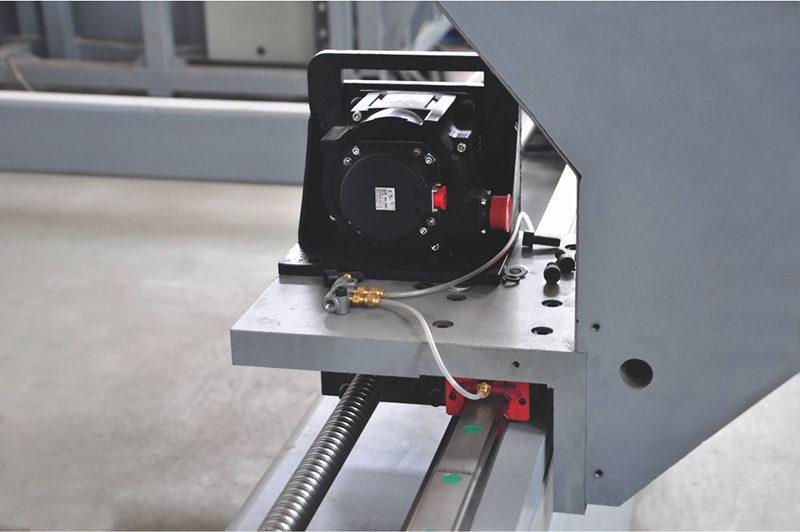

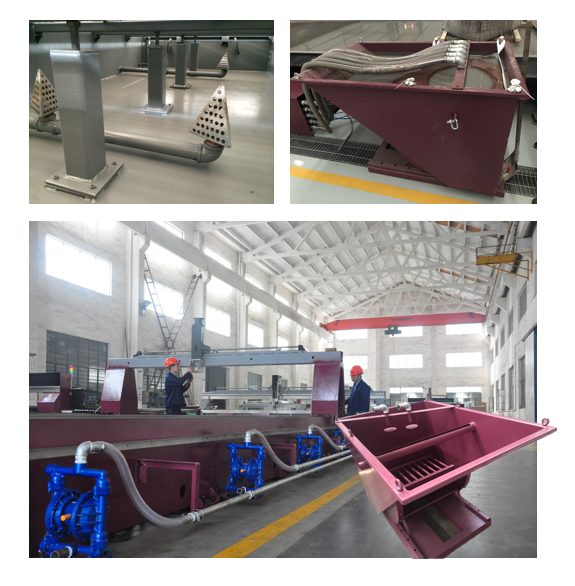

Detalles de la mesa de corte

|

|

|

|

|

|

|

|

|

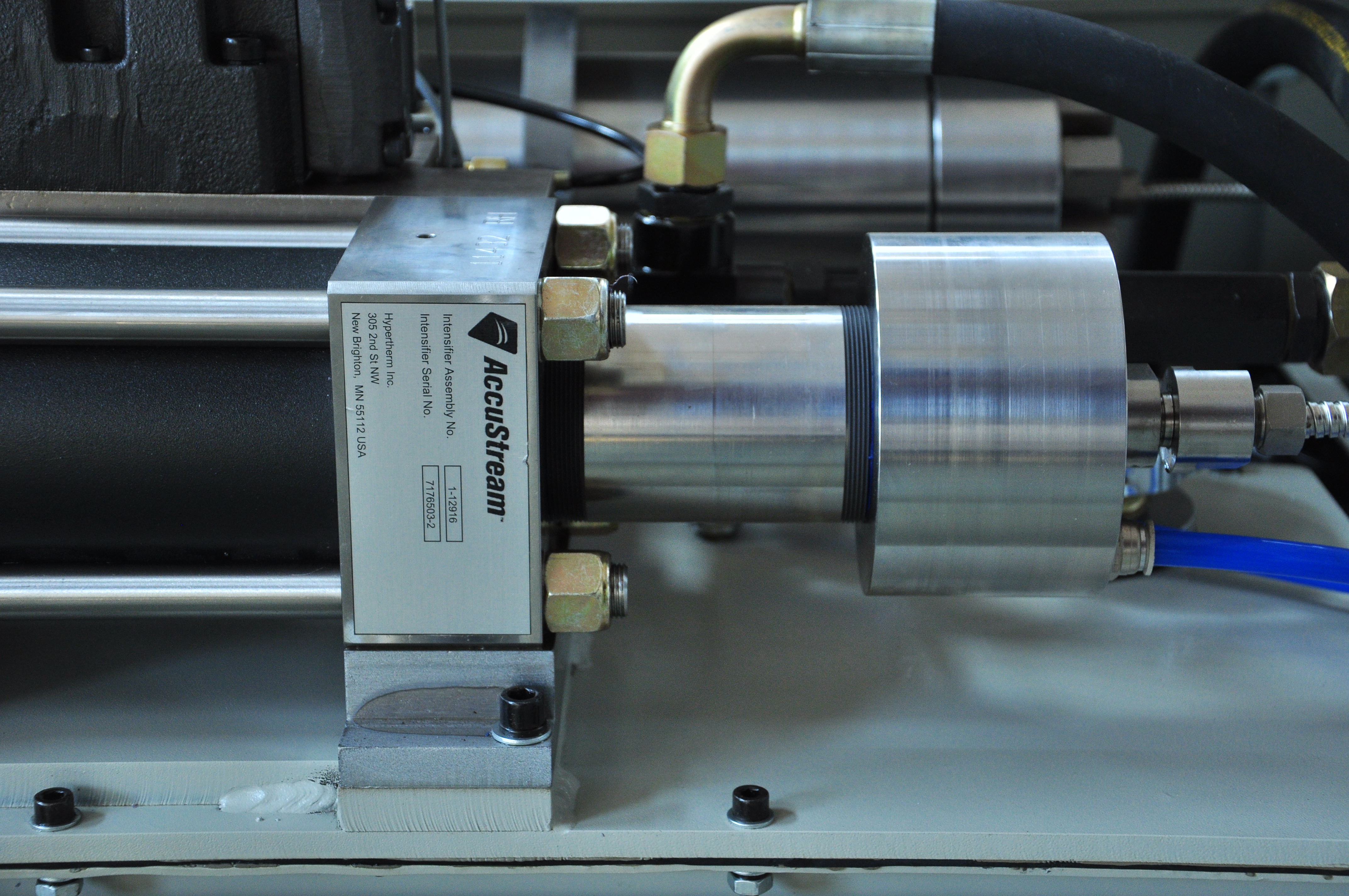

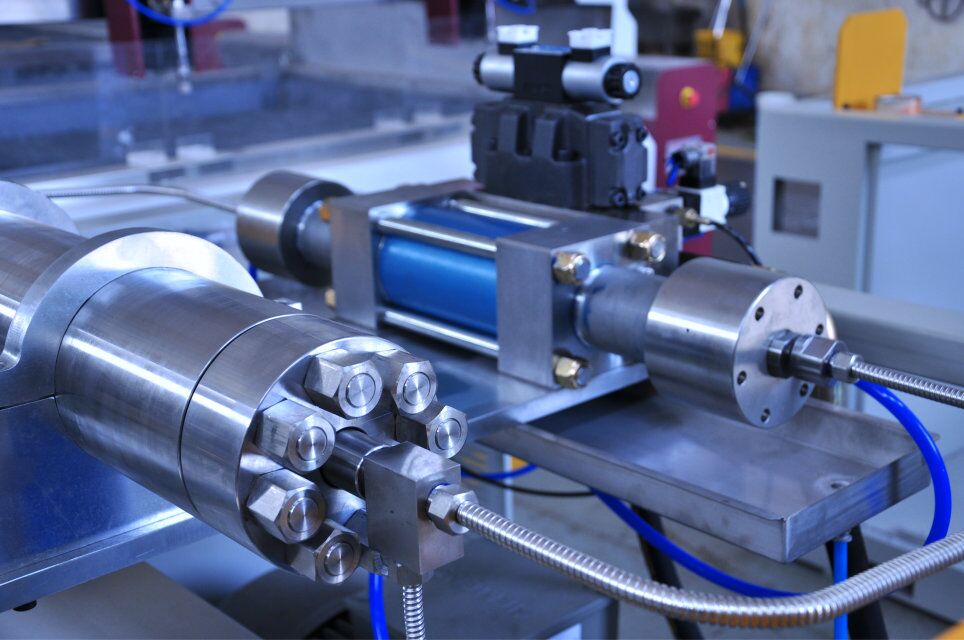

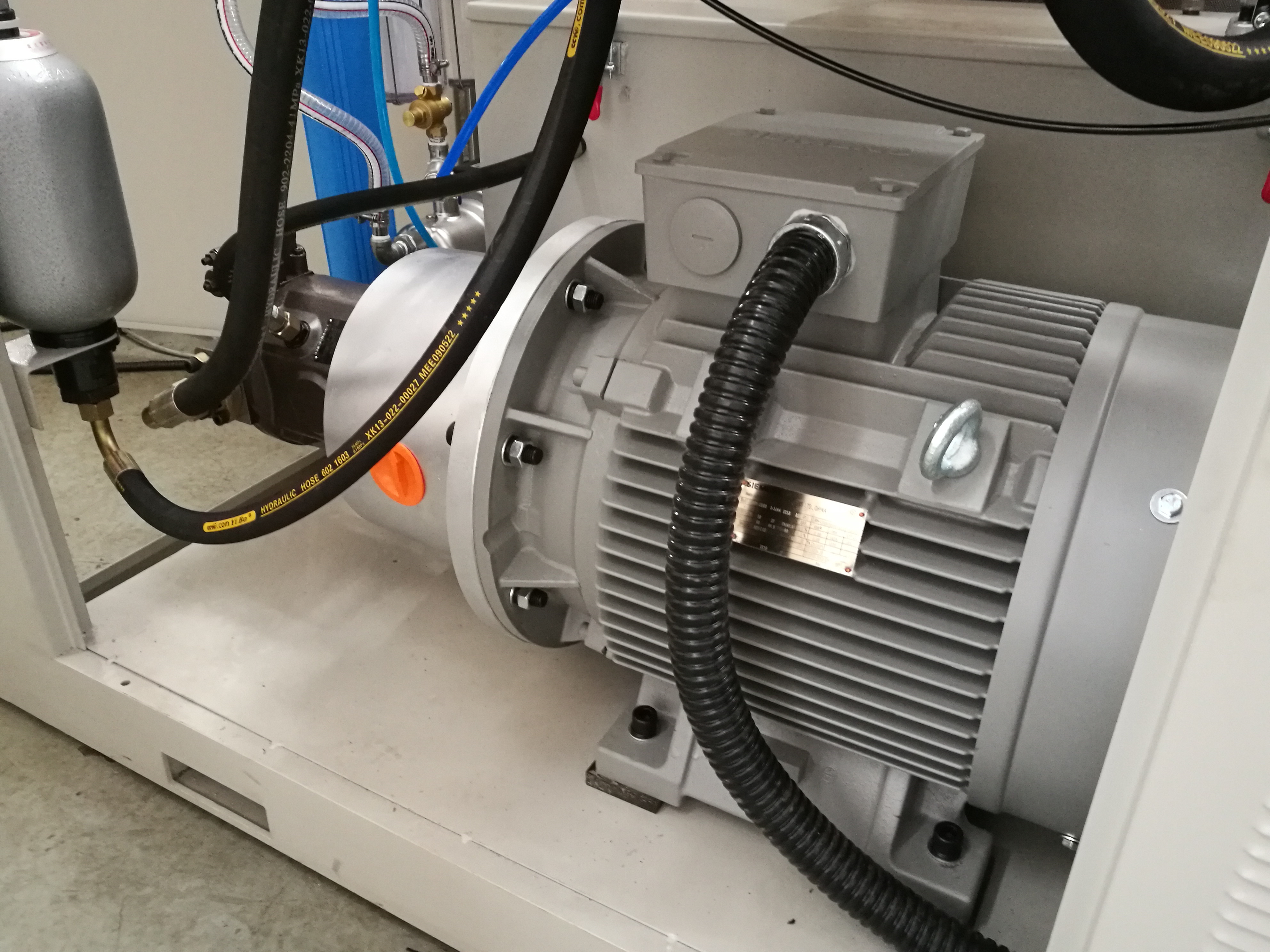

Bomba de alta presión

|

High Pressure Pump Main Feature: Control: PLC Shifting: electro-hydraulic Control Cooling: cooler/oil heat exchanger Inlet water filter accuracy: ≤0.45μm Oil-return filter accuracy: 20 μm Working temp: 0-50°c Outlet: UNF 3/8" Cooling in/out-let: NPT1" Max orifice size: 0.33mm

Siemens or YASKAWA motor

The high pressure pump designed by our company is easier to install and maintain, and the working pressure is stable, which fully ensures the working efficiency.

The whole set of intensifier assembly or main parts of intensifier assembly are imported from USA (Accustream/Hypertherm) directly.We are the partner of Hypertherm.

|

|

|

|

|

|

|

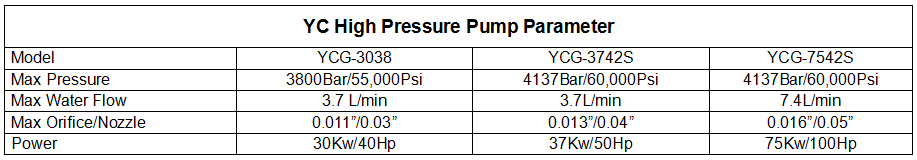

Otra serie r de bombas de alta presión

|

|

|

| Double High Pressure Pump |

Servo high Pressure Pump |

Hypertherm High Pressure Pump |

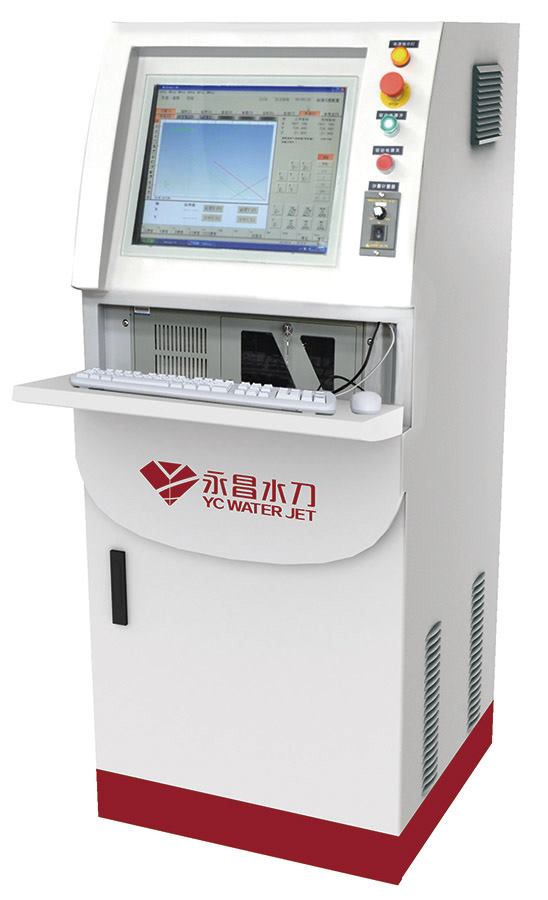

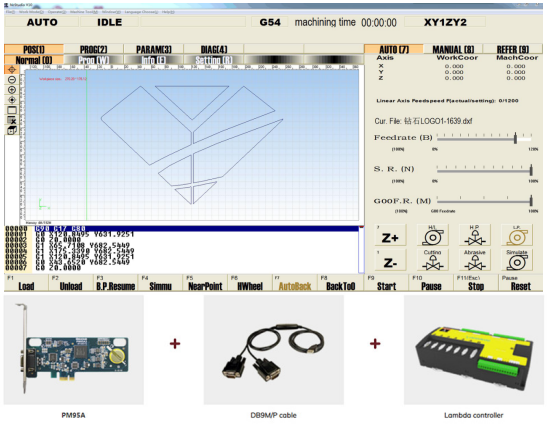

Controlador CNC

|

|

YC Waterjet Cnc Controller And Software(WEIHONG System) 1.17ʺLCD liquid crystal display. 2.DNC on-line working function. 3.Functions of returning arbitrary point, bending and circular are working auto deceleration. 4. Function of cutting figure imitation display. 5. 80GB memory hard disk. 6. MITSUBISHI AC servo driver and motor. 7. 1GB memory card. 8. Multilingual function(Chinese English etc.). 9. Drive-by-wire and hand-hold controller. 10. NAIKY PCIMC-6A special software is special for YC. Noted:You can also choose the Italian ECS or ESA control system.

|

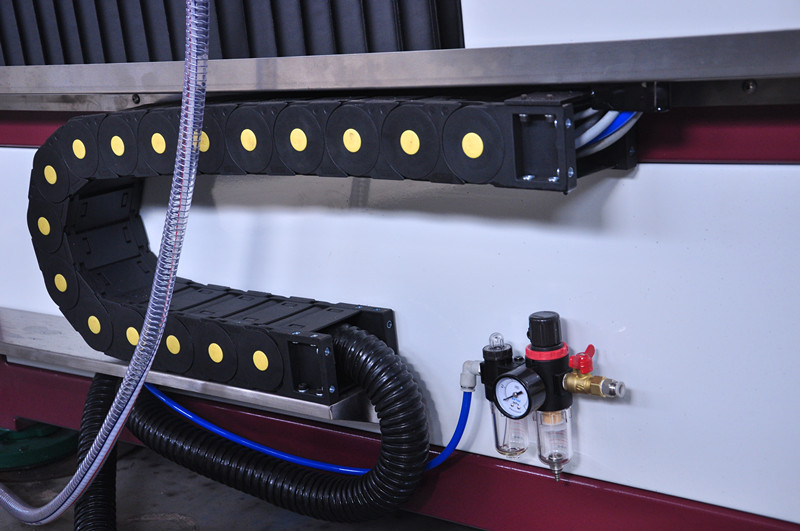

Sistema de alimentación de abrasivo y sistema de enfriamiento

|

|

|

| Abrasive feeding system | Air cooling system | Oil cooling system |

Elemento opcional para máquina de chorro de agua

|

Waterjet Auto Sludge remove systemRemove the abrasive from the tank automatically, separate the abrasive and water.Reduce the labor force,improve work efficiency.The absorption pump sucks up the mixture of sand and water from the tank into a collection box when it works.There are plastic woven filter bags in the collection box,water is recycled to the machine tank, sand and the mixturefrom cutting are collected into filter bags Inside. So as to achieve the purpose of automatic collection to make it easy to clean.

DATA OF ABSORPTION PUMP |

|

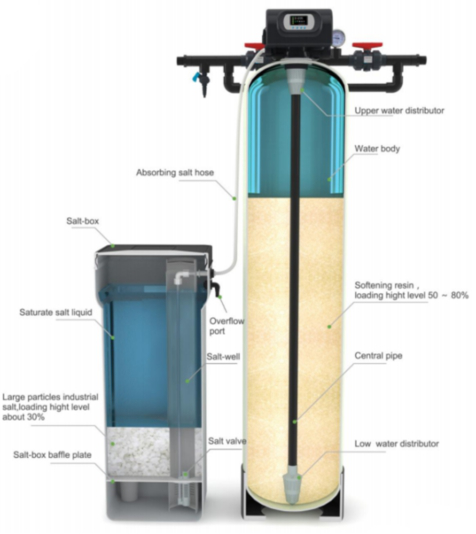

Water Jet Soften Treatment Many kinds of compounds exist in the running water (such as calcium carbonate, carbonic acid). As the machine works, the temperature rise will generate some substance of the reaction of chemistry or physics-as we called it furring, which will reduce the life of the high pressure system and increase the cost. After many years' experience, we have developed the system that can solve the problem. We would like to recommend you this optional part if your supplied water is low quality.

Quality requirement for water |

|

|

|

Hydraulic Loading System |

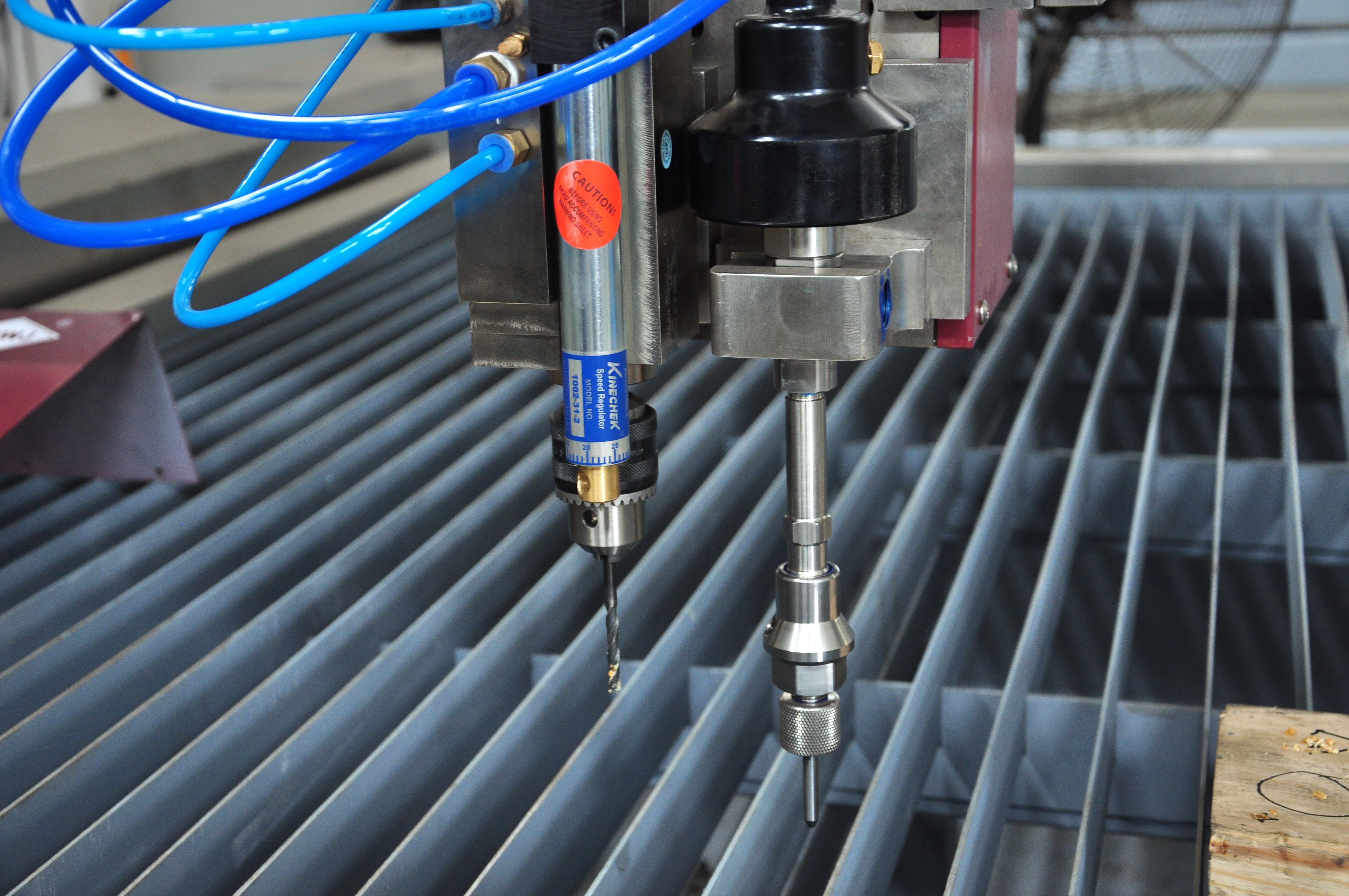

Water Jet Cutting Head With Drilling Function |

Productos relacionados

|

|

|

|

Dynamic 5axis Waterjet Machine

(Bevel Cutting 0-±10°) |

Max 5axis WaterJet Cutting Machine (Bevel Cutting 0-±45°) |

Pure water waterjet cutting machine |

|

|

|

|

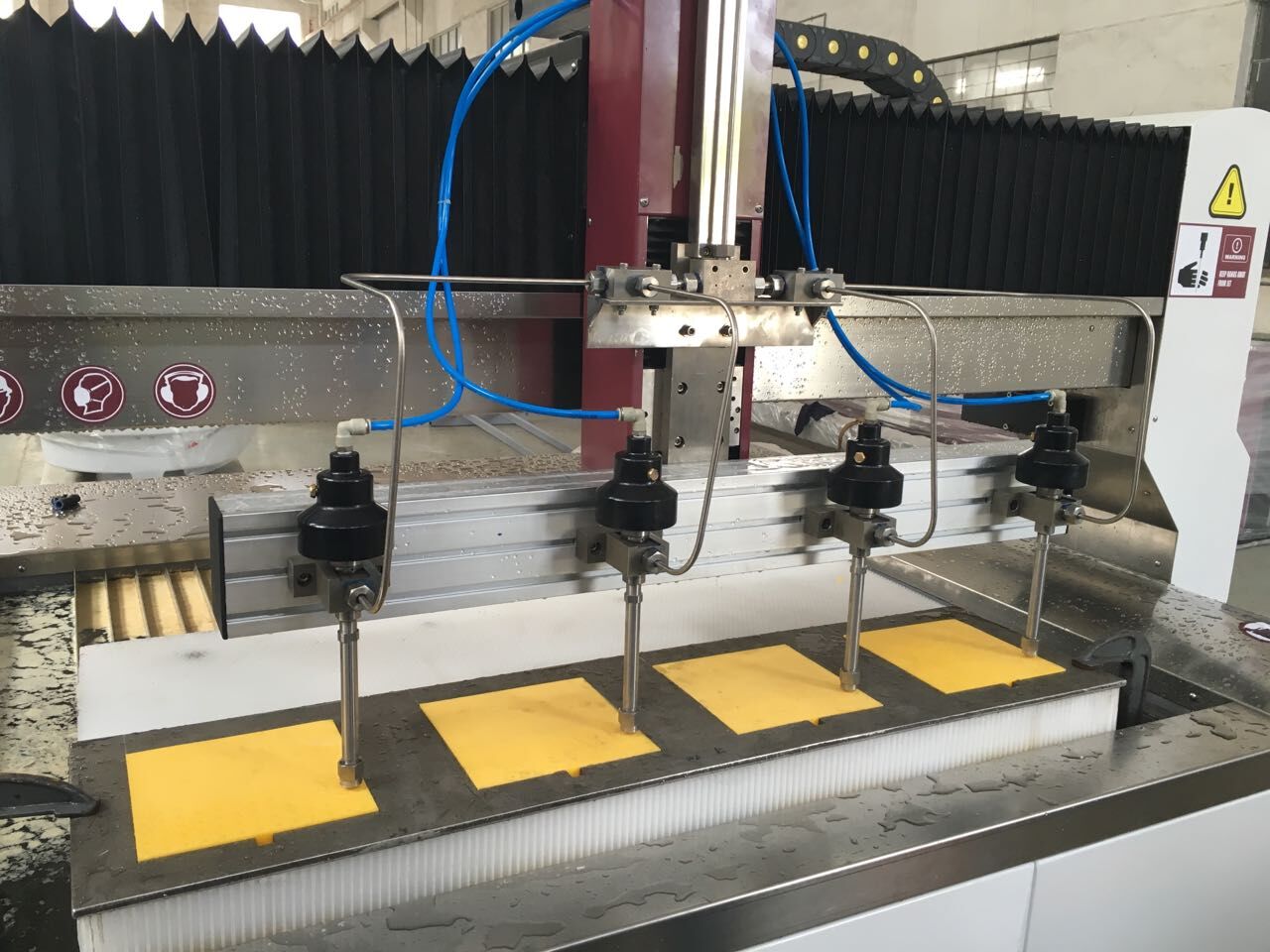

Multi- heads Machine |

Cantilever Waterjet Cutting Machine

|

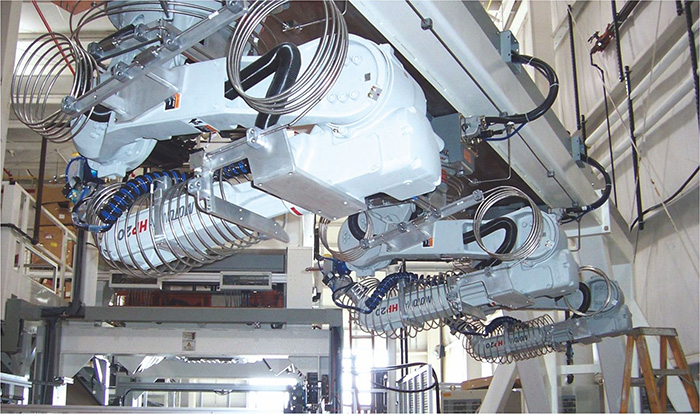

Robotic Waterjet Cutting Machine |

Muestras de corte

Embalaje y entrega

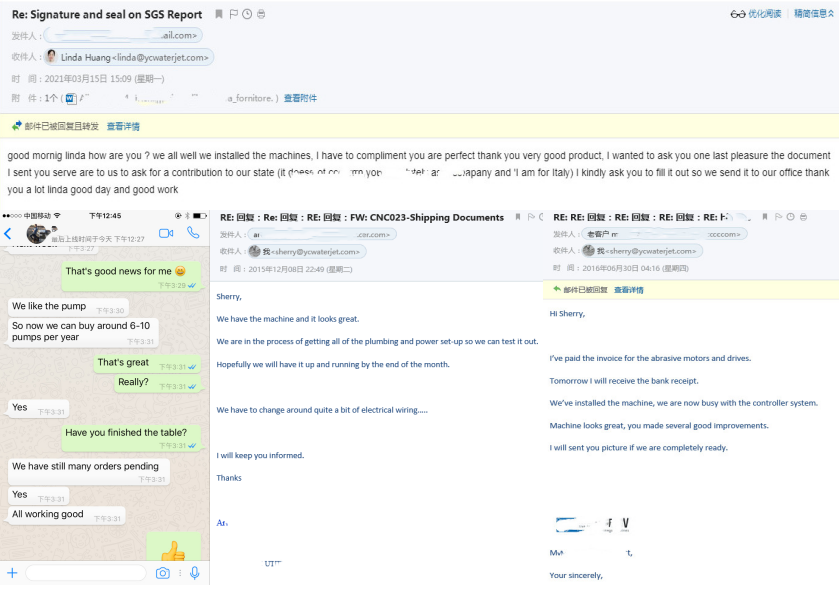

Comentarios de los clientes

Nuestro servicio

Servicio de preventa

Información de la empresa

|

Development1999, YC Industry was established by Mr. Min, mainly engaged in manufacturing large production line. 2005, YC started to research and developed UHP water jet cutting equipment and cooperated with German KMT as well.

2008, YC started to cooperate with the UK agent. 2019,YC has sold the products to more than 50 countries . |

Why usWe are engaged in machinery manufacturing since the year 1999,there are more than 20% workers with more than 8 years experience in water jet cutting field.Our chief engineer Mr. Tian who started research of water jet when he was a university student has 20 years experience in water jet cutting field, and other technical persons have over 10 years experience.

For different customers in different industries we will provide different solutions, Your water jet is tailored based on your individual needs.

|

Certificaciones

Grupos de Producto : Máquina de chorro de agua > Máquina de tipo integral serie L